Mechanical stress concentration:

When the surface flatness of IGBT chips is poor, there may be uneven areas on the chip surface. These areas may experience mechanical stress concentration due to uneven stress distribution when subjected to external forces.

Long term mechanical stress concentration may lead to cracks or damage inside the chip, thereby affecting the electrical performance and reliability of the chip.

Decreased heat dissipation performance:

IGBT generates a large amount of heat during operation, which needs to be promptly dissipated through a cooling system. If the surface flatness of the chip is poor, it may affect the contact area and tightness between the heat dissipation system and the chip.

The reduction of contact area and the decrease of contact tightness will lead to a decrease in heat dissipation performance, resulting in an increase in the internal temperature of the chip. High temperature will accelerate the aging process of chips and reduce their service life.

Bond wire detachment:

IGBT chips are usually connected to external circuits through bonding wires. If the surface flatness of the chip is poor, it may result in a weak connection between the bonding wire and the chip.

During long-term operation, due to the influence of current load and temperature changes, the bonding wire may detach or break, leading to circuit failure.

2、 IGBT short-circuit failure mechanism

Internal short circuit:

When cracks, damage, or impurities appear inside the IGBT, it may cause an internal short circuit. Internal short circuits can generate significant transient currents, leading to device overheating and damage.

External short circuit:

Short circuit faults in external circuits may also cause IGBT damage. For example, when a short circuit occurs at the load end, IGBT may be subjected to excessive current and voltage surges, leading to short-circuit failure.

3、 The correlation between poor flatness and short-circuit failure

Indirect impact:

Although poor surface flatness of chips does not directly cause IGBT short-circuit failure, it increases the risk of short-circuit failure through indirect factors such as affecting heat dissipation performance and bonding wire connection quality.

Comprehensive function:

In practical work, the failure of IGBT is often the result of a combination of multiple factors. Poor surface flatness of chips may work together with other factors such as temperature cycling, power cycling, material aging, etc., to accelerate the failure process of IGBTs.

4、 Response measures

Improve chip flatness:

In the manufacturing process of IGBT chips, the production process and parameters should be strictly controlled to ensure that the flatness of the chip surface meets the requirements.

Strengthen heat dissipation design:

Optimize the heat dissipation design of IGBT modules, improve heat dissipation efficiency, and reduce the operating temperature of chips.

Regular inspection and maintenance:

Regularly inspect and maintain IGBT modules, promptly identify and address potential faults and issues.

In summary, there is a certain correlation between the poor surface flatness of IGBT chips and the short-circuit failure mechanism of IGBT. Therefore, in the manufacturing, use, and maintenance process of IGBT, the flatness of the chip surface should be highly valued, and effective measures should be taken to solve it.

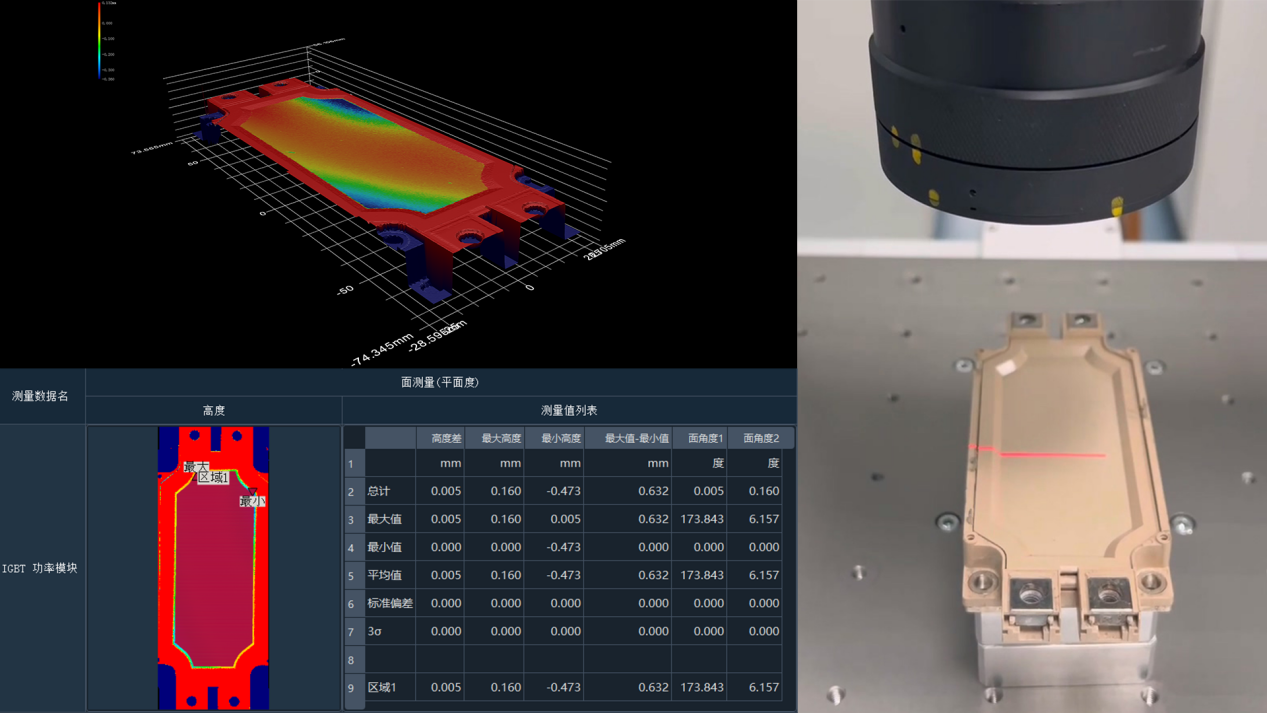

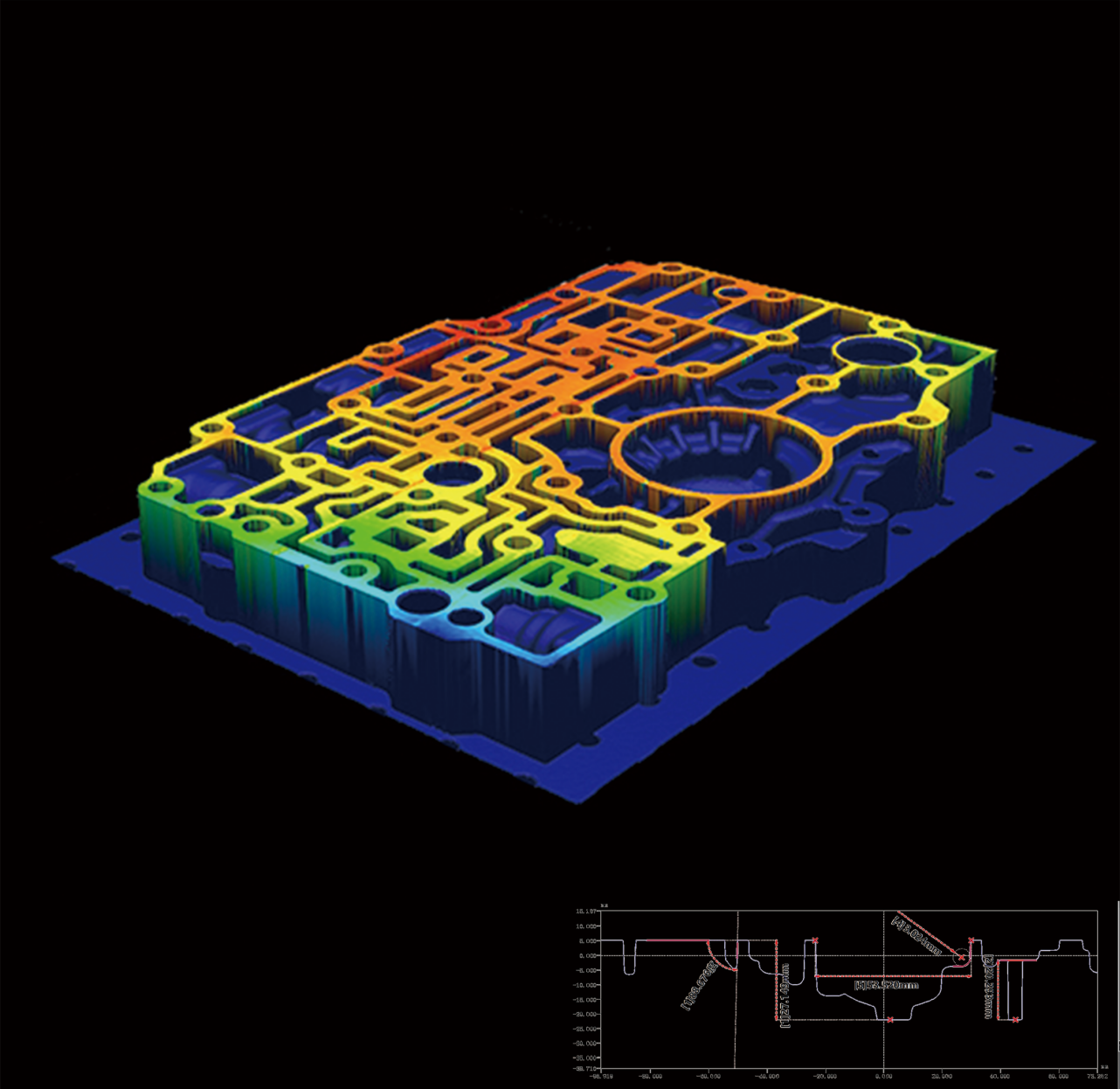

IGBT package bonding flatness test case: (Color temperature chart represents 3D high and low information, table shows measured deformation)

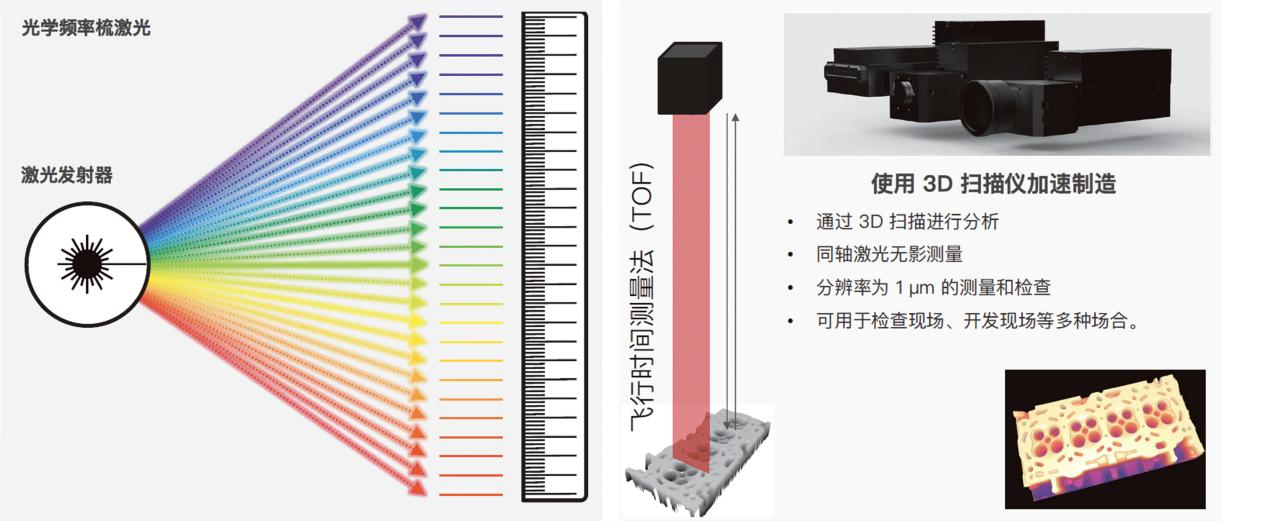

4、 Introduction to Laser Frequency Comb 3D Optical Contour Measurement System

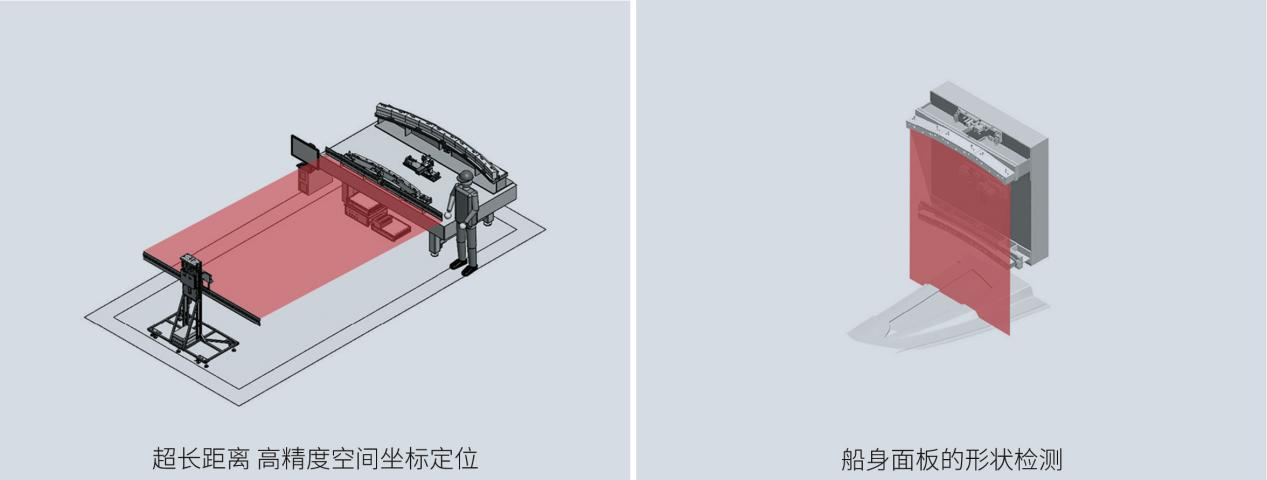

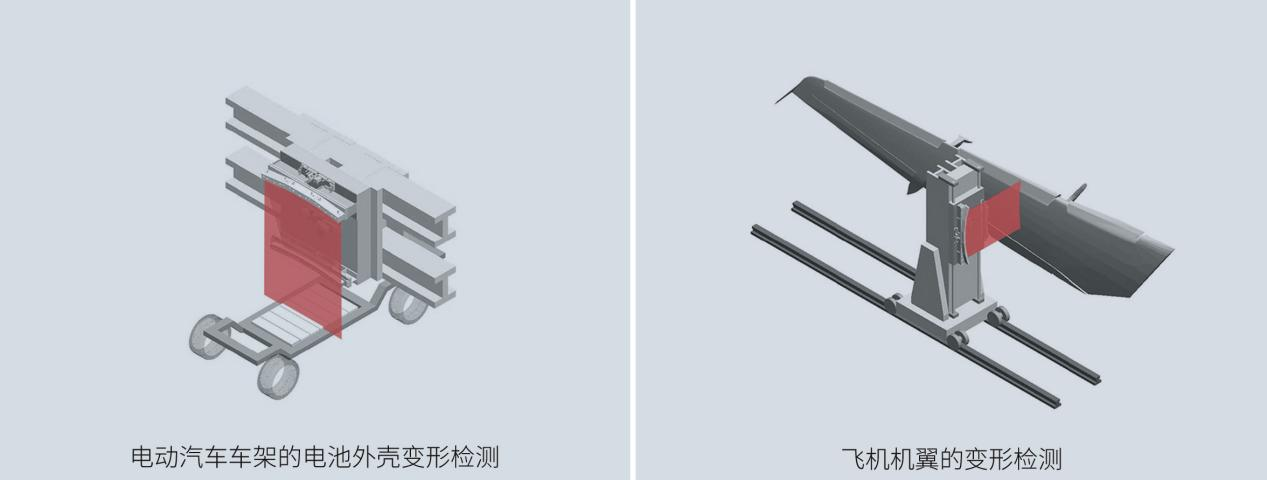

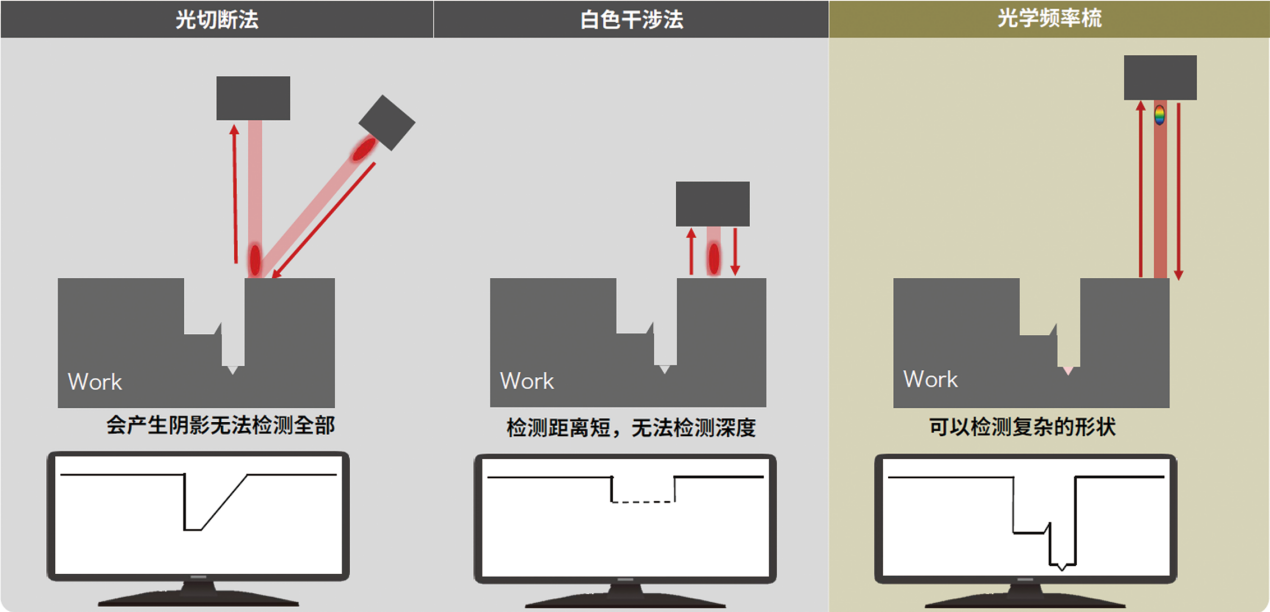

The laser optical frequency comb 3D contour measurement system utilizes the principle of laser frequency comb and adopts high-frequency laser pulse flight distance measurement method, which is not afraid of traditional optical obstruction problems and fully applicable to the measurement of various complex large structural components, solving the difficulties of traditional optical measurement such as deep holes and grooves. The laser frequency of 500kHz has brought technological innovation to the automation of detection.

Technical feature one: coaxial shooting, flight ranging scanning method, not afraid of traditional optical "obstruction" problems.

Actual case: Valve body oil circuit board with vertical and horizontal grooves

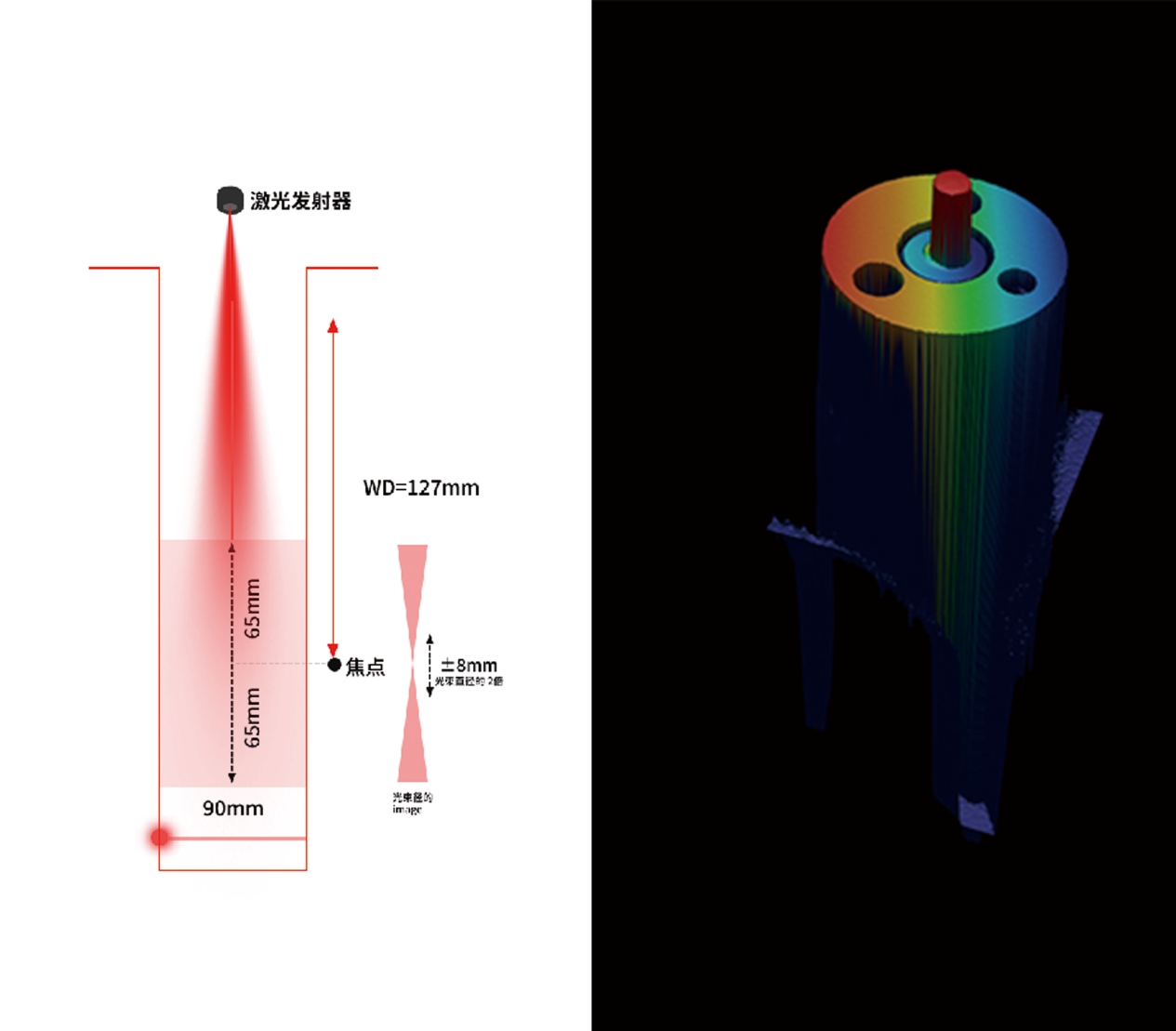

Technical feature 2: With an accuracy of ± 2um, it can achieve a maximum height/depth scanning imaging of 130mm

Technical feature three: It can be equipped with multiple lens combinations to achieve scanning with a large field of view of tens of meters.